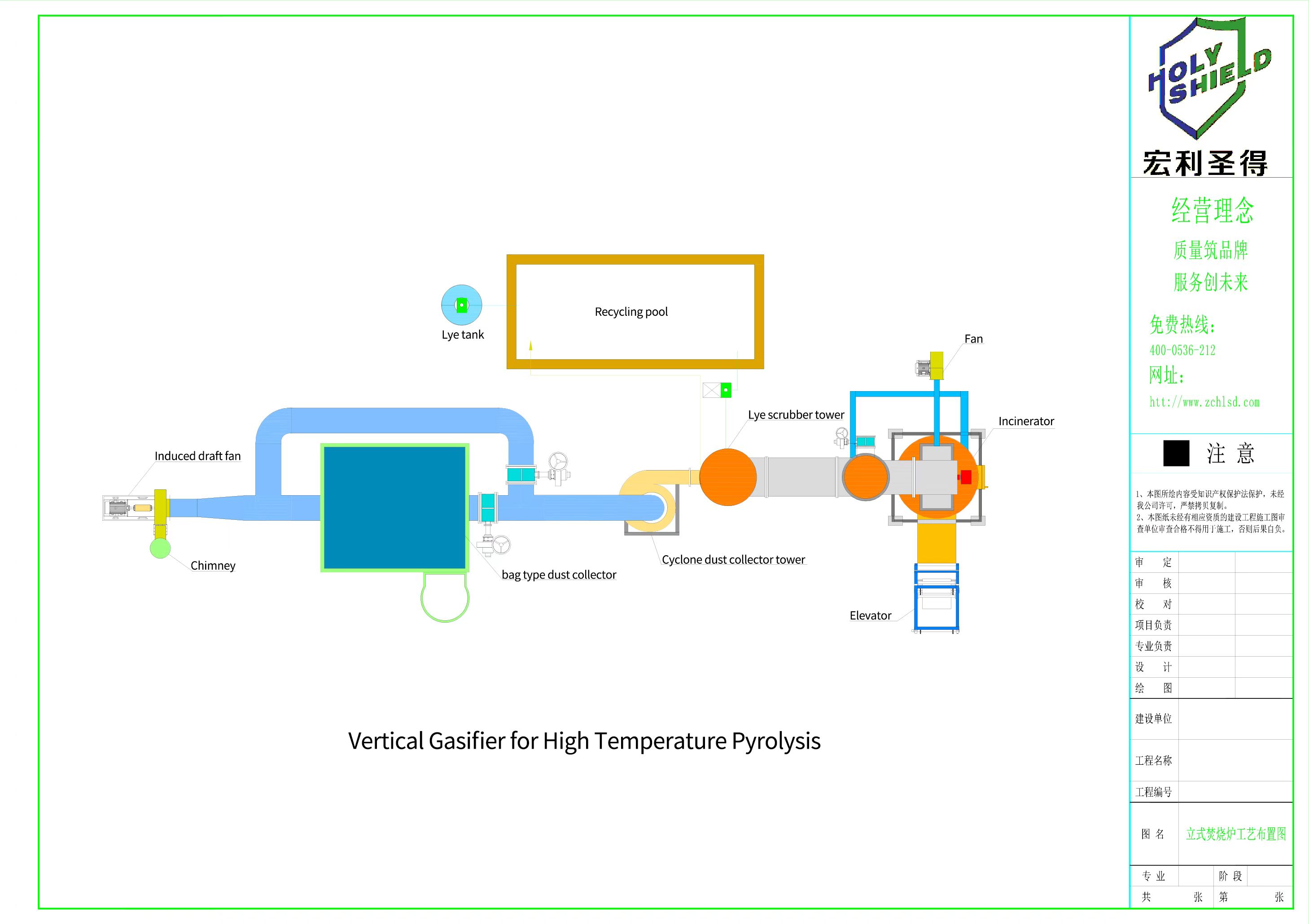

New high-temperature pyrolysis gasification technology is adopted, including primary pyrolysis gasification + surrounding air mixed combustion + secondary incineration + burn-out treatment. The combustible gas is fully decomposed in the secondary combustion chamber at a high temperature of 850-1200°C to realize harmlessness, reduction, and resource treatment of the solid waste.

Smokeless and odorless, meeting emission standards

The emission from the incinerator is smokeless and odorless, meeting the emission standards.

High temperature pyrolysis gasification technology

New high-temperature pyrolysis gasification technology, high-temperature incineration treatment, safe and pollution-free.

Simple structure and easy operation

Automatic control system, automatic temperature control, digital display, easy to operate and use. Plastic bags

Plastic bags

woven bags

woven bags

rubber products

rubber products

leather

leather

tires

tires

paint residue

paint residue

clothing scraps

clothing scraps

slippers scraps

slippers scraps

| Model | Land area(㎡) | Power(kw) | Chimney(mm) | Weight(kg) | Operation voltage(V) |

| HLPG-20-2 | 900*600*700 | 0.44 | Φ140*6m | 1500 | 380or220 |

| HLPG-30-2 | 1450*900*1020 | 0.63 | Φ159*6m | 2000 | 380or220 |

| HLPG-50-2 | 1800*1160*1200 | 0.81 | Φ219*6m | 3000 | 380or220 |

| HLPG-150-2 | 2000*1200*1360 | 1.01 | Φ219*6m | 4500 | 380or220 |

| HLPG-300-2 | 2200*1570*1510 | 1.8 | Φ530*6m | 8500 | 380or220 |

| HLPG-500-2 | 3000*1750*1710 | 3.34 | Φ620*6m | 12000 | 380or220 |

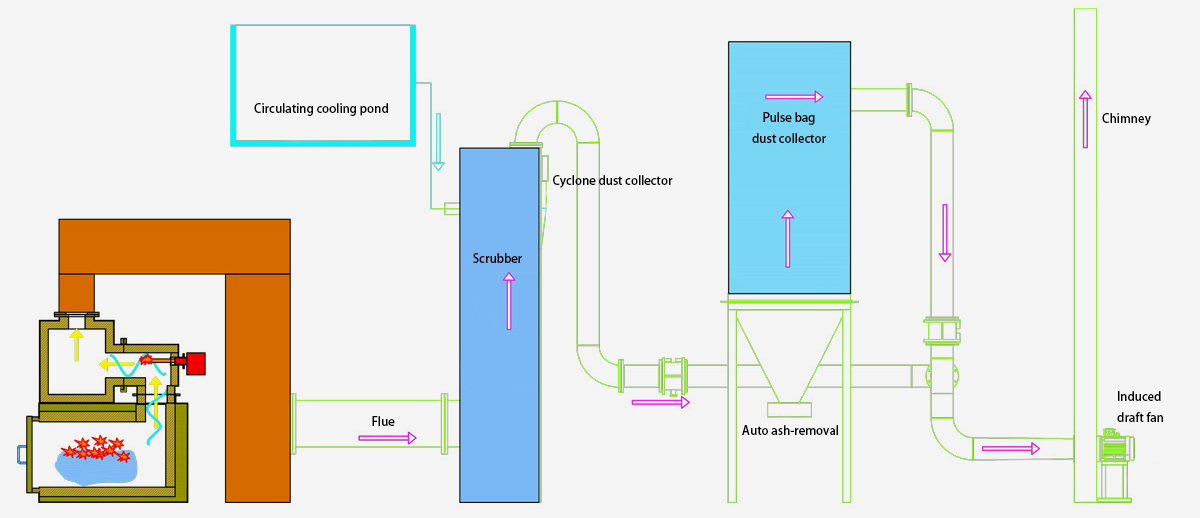

Stage1The high temperature gas discharged from the secondary combustion chamber is treated by the flue gas scrubber, and the temperature is reduced from 850°C to 180°C in 2s, which effectively overcomes the secondary synthesis conditions of dioxin; secondly, being atomized by the special nozzle , it performs synchronous disconnection Sulfur Denitrification.

Stage1The high temperature gas discharged from the secondary combustion chamber is treated by the flue gas scrubber, and the temperature is reduced from 850°C to 180°C in 2s, which effectively overcomes the secondary synthesis conditions of dioxin; secondly, being atomized by the special nozzle , it performs synchronous disconnection Sulfur Denitrification.

Stage2Under the action of cyclone dust removal of the medium-efficiency dust collector, the particulate matter in the gas and the large particulate matter generated during the deacidification process would be separated from the cooled and desulfurized gas effectively.

Stage2Under the action of cyclone dust removal of the medium-efficiency dust collector, the particulate matter in the gas and the large particulate matter generated during the deacidification process would be separated from the cooled and desulfurized gas effectively.

Stage3The exhausted flue gas is then treated effectively by a high-temperature pulse bag dust collector to filter remaining dust, heavy metals, dioxins and other components attached to the fine particles to effectively ensure that the exhaust gas treatment meets the standard.

Stage3The exhausted flue gas is then treated effectively by a high-temperature pulse bag dust collector to filter remaining dust, heavy metals, dioxins and other components attached to the fine particles to effectively ensure that the exhaust gas treatment meets the standard.

Stage4After precision filtration by the bag dust collector, the flue gas is discharged through the chimney under the action of the centrifugal fan.

Stage4After precision filtration by the bag dust collector, the flue gas is discharged through the chimney under the action of the centrifugal fan.

Support on-demand customization

Support on-demand customization  Customized garbage

Customized garbage  Customized appearance

Customized appearance  Customization of waste

Customization of waste  Design

Design

Customization production

Customization production

Design civil engineering drawings

Design civil engineering drawings

Construction direction

Construction direction

Installation and commissioning

Installation and commissioning