The

mobile hazardous waste incinerator is a device that incinerates and disposes of hazardous waste. How does this device operate and how does it work? Read on,

holy shield tells you!

1. The process flow of mobile hazardous waste incinerator:

⑴ Section name: Feeding Section brief description: Through the steps of compatibility, transportation, etc., the waste to be disposed of is reasonably matched to the incineration disposal requirements, which is conducive to the complete decomposition of the waste in the subsequent incineration process.

(2) Section name: Incineration and disposal Section brief description: Through the primary combustion and secondary combustion of the rotary kiln, the hazardous waste can be completely incinerated at 800-1300 ℃, ensuring the 99.999% incineration rate limited in the process control.

(3) Section name: Brief description of the flue gas cooling section: Through the steps of waste heat recovery, rapid cooling, etc., the temperature of the flue gas discharged from the secondary combustion chamber is reduced to below 200 °C; At 600°C, during the cooling process, the heat source is recovered and provided to other facilities in the plant area to ensure the reuse of heat resources; rapid cooling reduces the flue gas temperature from 600°C to 200°C in one second, minimizing the re-production of dioxins. synthesis.

⑷ Name of the section: Brief description of the exhaust gas washing section: The removal efficiency of acidic pollutants is ensured by two-step deacidification of dry and wet methods; the organic combination of the world's leading membrane separation technology and activated carbon adsorption technology is adopted to ensure the pollution of soot, dioxins and heavy metals. removal efficiency.

⑸ Name of the section: exhaust gas detection and emission Brief description of the section: the online monitoring system monitors the pollutant discharge in real time throughout the whole process, and the tail gas discharge meets the GB18484-2001 "Hazardous Waste Incineration Pollution Control Standard".

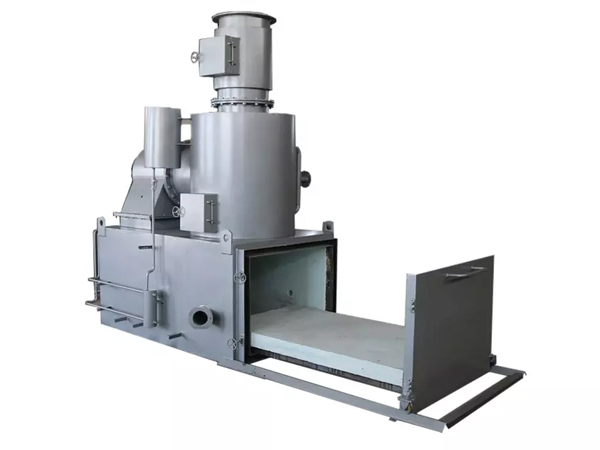

2. Device configuration of mobile hazardous waste incinerator:

Pretreatment and feeding system: rotary kiln + secondary combustion chamber combustion system + waste heat recovery system + tail gas purification treatment system + flue gas discharge device.

Incineration system: including hopper, rotary kiln, secondary combustion chamber, and auxiliary equipment such as combustion support and fan.

Waste heat recovery system: including waste heat boiler and boiler auxiliary system equipment.

Flue gas purification system: Cool the flue gas in the incinerator and remove harmful substances, and discharge it after meeting the emission requirements. Including quench tower, dust collector, washing tower, flue gas heater, activated carbon supply system, ash removal system, etc.

Flue gas emission system: including induced draft fan, chimney, etc.

3. Characteristics of the pretreatment process of mobile hazardous waste incinerator:

A. The feeding door of the solid waste storage pool adopts an automatic control sealing door system controlled by infrared rays. When the conveying vehicle enters the storage area, the sealing door is automatically opened for discharging, and the sealing door is automatically closed when the discharging is completed to ensure that the storage pool is kept fully sealed. working under negative pressure.

B. The solid waste storage pool adopts steel concrete structure, and is covered with multiple layers of anti-corrosion materials. The lowest point of the storage pool is set with a seepage pit and a pump.

C. The process of storage, compatibility and control and adjustment of solid hazardous waste can be realized in the storage tank.