With the continuous development of technology, the thermal energy utilization technology of waste incineration plants is also constantly improving. How to improve the thermal energy utilization efficiency of waste incinerators? Holy Shield will be discussed in detail below.

1. Comprehensively improve the thermal system

During the operation of the thermal system, the loss of thermal energy is relatively large, so it is necessary to comprehensively improve the thermal system to improve the utilization rate of thermal energy. First of all, under normal working conditions, all the steam generated by the waste boiler needs to be used for heating and power generation of the gas turbine generator set. The second is to carry out the scientific selection of the extraction unit, so as to ensure that the efficiency of the regenerative cycle is increased.

2. Enhance boiler outlet steam parameters

The power plant established in the waste incineration process is a small thermal power plant. To increase the pressure of its own power generation working fluid, it is necessary to increase the pressure level of the thermal equipment itself. If the temperature during the waste incineration process is not high, it is necessary to use a very expensive thermal power plant. High temperature corrodes metal materials, and the cost of making materials for superheaters will greatly increase. Therefore, in the process of improving the boiler outlet steam parameters, it is necessary to compare the equipment input with the output efficiency to achieve the optimal matching of the steam turbine generator set, so as to improve the boiler steam outlet parameters and reduce the cost input.

3. Advance disposal of garbage

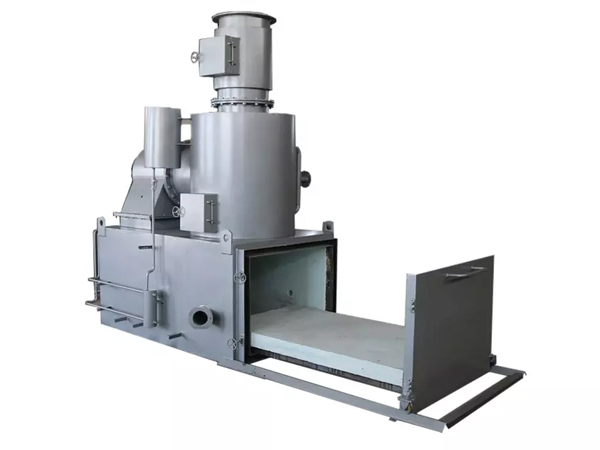

First of all, for the garbage that needs to enter the boiler for incineration treatment, it can be fermented in advance to drain the leachate existing in the garbage. Secondly, some inorganic garbage will sink to the bottom of the storage tank for dehydration and weight reduction. Stirring these garbage can increase the low calorific value of the garbage per unit mass during the garbage incineration process, and realize the complete combustion of the garbage in the garbage incinerator, improve the combustion efficiency of waste. For waste incineration boilers, the flue gas generated in the actual operation process is extremely corrosive, which will affect the improvement of boiler steam parameters. Therefore, it is necessary to scientifically select the waste incineration treatment equipment to minimize the heat dissipation loss of the incineration boiler itself, so as to improve the utilization efficiency of thermal energy during the waste incineration process. Holy Shield's incinerator may be the most suitable choice for you, buy it now!

For waste incineration boilers, the flue gas generated in the actual operation process is extremely corrosive, which will affect the improvement of boiler steam parameters. Therefore, it is necessary to scientifically select the waste incineration treatment equipment to minimize the heat dissipation loss of the incineration boiler itself, so as to improve the utilization efficiency of thermal energy during the waste incineration process. Holy Shield's incinerator may be the most suitable choice for you, buy it now!