Holy Shield has always focused on the research of solid waste treatment, and today I will share with you the "Research on the Control of Heavy Metal Pollution from Waste Incineration".

Generally, it can be divided into three aspects: control before incineration, control during incineration and control after incineration.

1.Control before incineration:

Sorting and sorting waste, and sorting out waste batteries, electrical appliances, and impurities with high concentrations of heavy metals from primary waste can greatly reduce the content of mercury, lead and cadmium in waste incineration products.

2.Control during incineration:

The

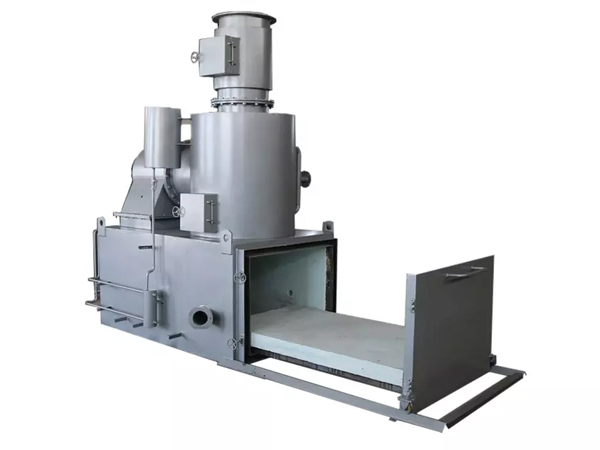

waste incinerator of holy shield mainly adopts the controlled air combustion method (CAO), that is, the waste is pyrolyzed, gasified and burned with fixed carbon in a combustion chamber of about 600~650e, so that the heavy metals will not sublimate, but remain in the ash. The combustible gas burns out at high temperature in the secondary combustion chamber, thereby reducing the emission of heavy metals during the combustion process.

3.Control after incineration:

(1) Cooling causes the heavy metals to naturally condense into nuclei or condense into granules and then be captured by the dust removal equipment;

(2) Spray powder such as activated carbon to adsorb heavy metals to form larger particles that are captured by dust removal equipment;

(3) Catalytic transformation, changing the types of heavy metals, so that heavy metal elements with low saturation temperature form oxides or complexes with high saturation temperature and more easily condensed, which are captured by dust removal equipment;

(4) Pass the exhaust gas through a wet scrubber to remove water-soluble heavy metal compounds. For the adsorption of mercury, the most widely used method is to spray special reagents into the flue gas, such as reverse spraying Na2S into the flue gas to form HgS. Because of its insoluble and large particles, it is easier to capture, and the mercury removal rate reaches 60%~90%. %.

Holy shield has rich experience in R&D and can be customized according to waste disposal requirements. If you also have garbage disposal needs, please leave a message with us.